(951) 680-9595

2021 Bronco Parts & Accessories are in the Works!

Our Mechanical Engineers and CAD Designers have been hard at work engineering off-road ready parts and accessories for your Gen-6 Bronco. With the popularity of the new Bronco, we’re making sure to produce all the off-road parts and convenience accessories you’ll need to maximize your ride. The design phase of our production begins with identifying what parts we’d like to make. We then scan the vehicle, create CAD drawings of the parts, create physical prototypes to test fitment, and finally send the part into production.

Product Research & Development

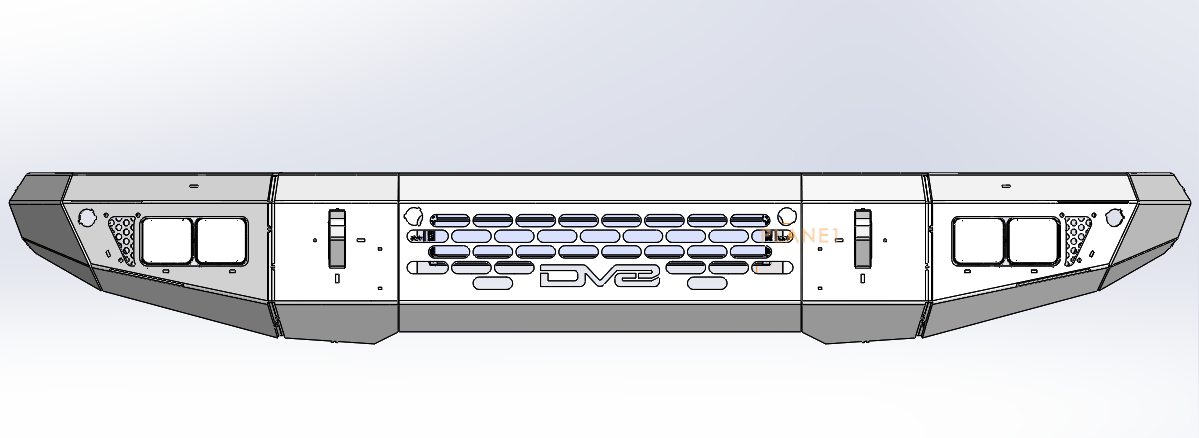

We begin by discussing what parts we’d like to make more functional for off-road driving, as well as how we want to bring our signature DV8 style into the part. The obvious first choices are Bronco front and rear bumpers. The idea is to increase ground clearance, while still protecting your Bronco, and to give it an aggressive style over the stock bumpers. We’re also taking a look at options for fenders, fender flares, and inner fender liners to better suit your style of rock crawling or Baja style off-road driving. Having said that, rock sliders are a must for any true off-road build, so we’ve designed options for you to protect those precious love handles on your Bronco. Light bar brackets and a roof rack round out that off-road build. Peering inside, we decided to design some interior parts for the sake of style. We also found that the rear cargo area could be enhanced with a cargo rack.

Body & Frame Scanning

This next phase of development involves scanning the body and frame of the Bronco in order to gather the data we need for our CAD artists to begin designing and engineering parts. We start by disassembling the area around the part in question in order to expose the mounting points and body/frame contours. For example, in making new fender flares/deletes, we remove the factory fender flare and scan both it and the wheel well in order to capture the body shape and mounting locations.

The scanning process involves using a double jointed Faro Arm. The arm extends from a heavy tripod base that sits stationary through the process. This is important, so that the laser gun and the software maintain the same anchor point when scanning an object. This is how the software ‘knows’ where objects are in a 3D space. Our Mechanical Design Engineers scan the vehicle from a distance of 6” - 8”. That data is funneled to the Faro software at the whopping rate of 60,000 points per second! These data points create a wire mesh of the object, which is then sent to our CAD Artists to begin work.

CAD Design

The CAD artist takes the mesh framework and creates planes/surfaces across the mesh. They then extrude the planes in order to make solid three-dimensional shapes to accurately recreate the frame and body of the Bronco. At this point, they are ready to begin digitally creating the parts we’ve set out to make. Because of the accuracy of the scanning process, they’re able to make precise 3D models of the Bronco bumpers, fenders, rock sliders, and so on. Once we’re happy with the digital version of a part, we then set out to make the first article.

First Article & Fitment

Once we create the first physical prototype, a front bumper for example, we then install it and ensure that it fits properly and looks great. At this point we can make any adjustments if needed, before we put it into production. Larger parts like bumpers and rock sliders are cut, bent, and welded like we would for production. Smaller cosmetic parts like shift knobs or interior bezels, are 3D printed and tested for fitment before going into production.

Bronco Parts & Accessories

We are currently in the First Article & Fitment stage of development for the Bronco. We’re getting close to having the best in Bronco Parts & Accessories available for you. Stayed tuned by following us on Instagram or Facebook!

Comments

Leave a comment